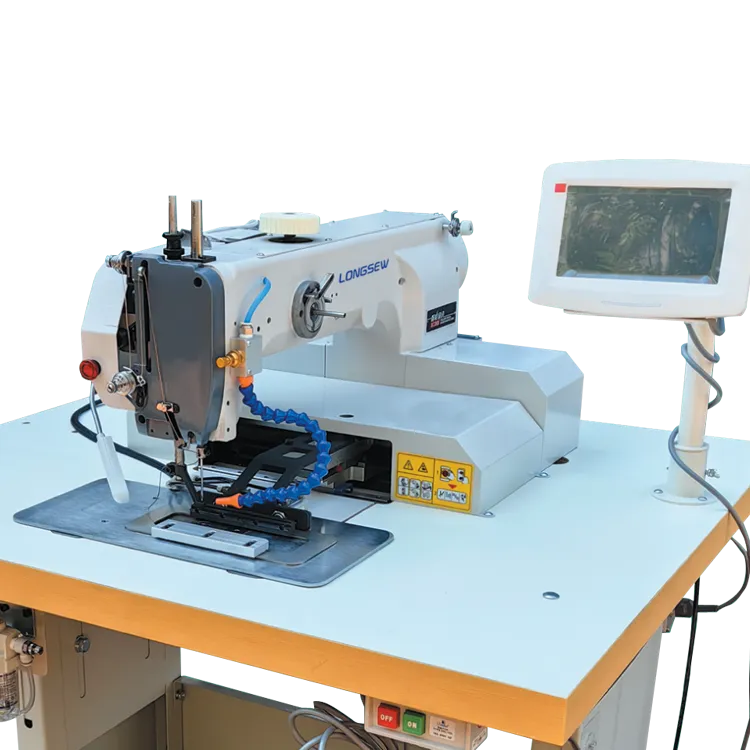

automatic overlock sewing machine

Latest articles

automatic overlock sewing machine

...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read More

automatic overlock sewing machineIn the world of sewing, precision and efficiency are paramount. Whether you’re a beginning hobbyist or an experienced tailor, having the right tools can make all the difference in the quality of your work. One particularly useful feature that has become standard in modern sewing machines is the automatic backstitch. This function not only simplifies the sewing process but also enhances the durability and professionalism of finished projects.

...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read MoreOne of the key advantages of using a 2% needle lockstitch machine is its ability to sew at high speeds without compromising on stitch quality. This makes it a valuable tool for businesses that require fast and efficient stitching, such as clothing factories and upholstery workshops.

automatic overlock sewing machine...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read More

automatic overlock sewing machineAn industrial serger machine, also known as an overlock sewing machine, is a type of sewing machine that uses multiple threads (usually two to five) to stitch and finish seams. Unlike traditional sewing machines that only create a single line of stitching, sergers can sew, cut, and finish edges all in one step. This capability not only saves time but also enhances the overall durability and stretch of the garment, making it ideal for stretchy fabrics like knits and jerseys.

...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read More

automatic overlock sewing machineIn recent years, the sewing industry has witnessed a significant surge in interest, particularly concerning serger machines. These specialized sewing machines have become a popular choice among both hobbyists and professional tailors, thanks to their ability to efficiently create clean and durable seams. As the demand for serger machines continues to grow, both manufacturers and retailers are responding with attractive sales and promotions.

...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read More

automatic overlock sewing machineConclusion

...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read More

automatic overlock sewing machineIn conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile manufacturing. Its efficiency, consistency, and technological advancements not only boost productivity but also help address sustainability concerns. As the fashion and textile industries continue to evolve, the hi-speed lockstitch machine will undoubtedly play a critical role in shaping the future of garment production, offering opportunities for both innovation and improved operational effectiveness. Embracing this technology is essential for manufacturers aiming to thrive in an increasingly competitive marketplace.

...

automatic overlock sewing machine 【automatic overlock sewing machine】

Read More

Popular articles

- In addition to their versatility, hand-held bag closer sewing machines are also known for their speed and efficiency. These machines are designed to quickly stitch bags together, saving time and labor costs for businesses. With the ability to sew bags at a rate of up to 13 meters per minute, hand-held bag closer sewing machines are a valuable tool for increasing productivity in various industries.

Heavy duty machines come with more robust standard attachments for tasks like hemming, ruffling, and binding on heavy fabrics. There are often additional attachments available like piping feet and binding folders to expand the abilities on heavy materials. Dual large spool pins allow quick and easy thread spool changes for continuous operation.

- One of the key benefits of heavy duty sewing machines is their durability and reliability. These machines are built to last, with sturdy construction and high-quality components that can withstand heavy use. In addition, heavy duty sewing machines are designed to handle high speeds and long hours of continuous operation, making them a valuable asset for businesses that require fast and efficient sewing.

Understanding the Price of Single Needle Quilting Machines

Upholstery is an art that blends creativity, design, and craftsmanship, allowing individuals to transform furniture pieces from ordinary to extraordinary. One of the essential tools for any upholsterer is the upholstery hand sewing machine. Unlike typical sewing machines, upholstery hand sewing machines are specially designed to handle heavy fabrics and materials that are commonly used in furniture upholstery, making them a vital addition to any craftsman's toolkit.

Latest articles

-

Making an Informed Purchase

-

In the world of textile crafts, few machines have made as significant an impact as the zigzag sewing machine. Unlike traditional straight-stitch machines, the zigzag sewing machine offers a multitude of stitching options that can elevate a sewing project from ordinary to extraordinary. This article delves into the features, uses, and benefits of zigzag sewing machines, highlighting why they are an essential tool for both amateur and professional seamstresses.

-

-

When sewing with heavy canvas, the right tools are crucial. Here are some essential items to consider

-

All walking foot sewing machines come with a cast iron finish and all metal working parts. Metal gears and parts will last much longer than any sewing machine with plastic gears and parts. Plastic gears and parts crack and break down quickly. Having a cast iron body proves to be much more durable than plastic bodies. If the machine drops, it will not shatter into 100 pieces. Durability is much higher with a walking foot sewing machine.

-

3. Production Capacity Machines designed for higher output will typically be more expensive. If a business requires high-speed production due to increased demand, investing in a more powerful machine can be a sound financial decision in the long run.

Links

- 4. Agricultural Applications In agriculture, fiberglass insulation tanks are used to store liquids such as irrigation water, fertilizers, and pesticides, ensuring that they remain at the desired temperature until needed.

- The manufacturing process of fiberglass water tanks involves layering fiberglass matting and weaving over a mold, followed by applying a resin binder. The layers are then cured to form a solid, seamless structure. This method ensures that the tanks are leak-proof and can withstand high pressure without compromising their integrity. Additionally, the smooth interior surface prevents the growth of bacteria and algae, ensuring cleaner water storage.

- FRP, or Fiberglass Reinforced Plastic, is a composite material that combines the strength of glass fibers with the flexibility of plastic resin. The result is a robust, lightweight, and corrosion-resistant material, ideal for manufacturing sump covers. A sump, essentially a low-lying area designed to collect water or other liquids, requires a secure cover to prevent accidents, unauthorized access, and maintain environmental standards.

- 9. Masonry hammer bits Made specifically for drilling through brick, block, and concrete, they exhibit superior strength.

- Carbon steel drill bits come in three primary types low-carbon, medium-carbon, and high-carbon. Low-carbon steel bits, with a carbon content typically below 0.35%, are more flexible but less durable, making them suitable for softer materials like wood. Medium-carbon bits, with a carbon content between 0.35% and 0.60%, strike a balance between strength and toughness, while high-carbon bits, with a carbon content above 0.60%, offer superior hardness and wear resistance, ideal for drilling into harder materials like metal.

- Fiberglass, or glass-reinforced plastic, is a composite material made by combining fine glass fibers with a resin matrix. The result is a lightweight yet incredibly strong material that can withstand heavy loads without deforming or breaking. In the context of ladders, this makes fiberglass an exceptional choice for those seeking stability and endurance.

- In addition to their durability, stone drill bits for hard rock must also be capable of efficiently penetrating tough rock formations

- Rock drilling is a crucial process in many industries, including mining, construction, and tunneling. One of the key components in rock drilling equipment is the button bit. Button bits are essential for drilling through hard rock formations efficiently and effectively.

- Moreover, the chemical resistance of fiberglass tanks extends to a multitude of chemicals, including acids, alkalis, solvents, and salts. This versatility allows them to be used in industries such as pharmaceuticals, petrochemicals, wastewater treatment, agriculture, and food processing, where the safe storage of diverse chemicals is paramount.

- However, the benefits of tungsten carbide mining button bits extend beyond their mechanical prowess. They contribute to environmental sustainability by facilitating precision drilling, which reduces the need for excessive blasting and subsequent environmental disturbance. Additionally, their high recyclability makes them a more eco-friendly option compared to other drilling solutions.

- GRP handrails are a type of railing system made from glass reinforced plastic, which is a material known for its strength, durability, and resistance to corrosion. This makes them an ideal choice for outdoor applications, where they can withstand the elements and provide long-lasting safety and protection.

- 10. Concrete hammer drill bits These bits, with their tungsten carbide tips, effortlessly drill through concrete without losing their edge.

Additionally, the center drill bit's design helps to transfer the cutting force from the drill to the workpiece more evenly, reducing the risk of breakage and improving overall stability Additionally, the center drill bit's design helps to transfer the cutting force from the drill to the workpiece more evenly, reducing the risk of breakage and improving overall stability

Additionally, the center drill bit's design helps to transfer the cutting force from the drill to the workpiece more evenly, reducing the risk of breakage and improving overall stability Additionally, the center drill bit's design helps to transfer the cutting force from the drill to the workpiece more evenly, reducing the risk of breakage and improving overall stability center drill bit.

center drill bit. Given their excellent radiation shielding properties, they are employed in the construction of containment vessels, piping systems, and radiation shields Given their excellent radiation shielding properties, they are employed in the construction of containment vessels, piping systems, and radiation shields

Given their excellent radiation shielding properties, they are employed in the construction of containment vessels, piping systems, and radiation shields Given their excellent radiation shielding properties, they are employed in the construction of containment vessels, piping systems, and radiation shields frp products for thermal and nuclear power. These materials help to mitigate radiation exposure to personnel and protect the integrity of the reactor infrastructure. Moreover, the non-corrosive nature of FRP ensures long-term reliability, reducing the risk of leaks or structural failures.

frp products for thermal and nuclear power. These materials help to mitigate radiation exposure to personnel and protect the integrity of the reactor infrastructure. Moreover, the non-corrosive nature of FRP ensures long-term reliability, reducing the risk of leaks or structural failures.